Production Control System

Our production control system makes it possible to manufacture quality products at optimum production efficiency and always deliver on schedule.

MELTING AND CASTING

Our state-of-the-art horizontal continuous pressure casting machine works in concert with an electromagnetic stirrer to produce billets with stable ingredients and refined grain structures.

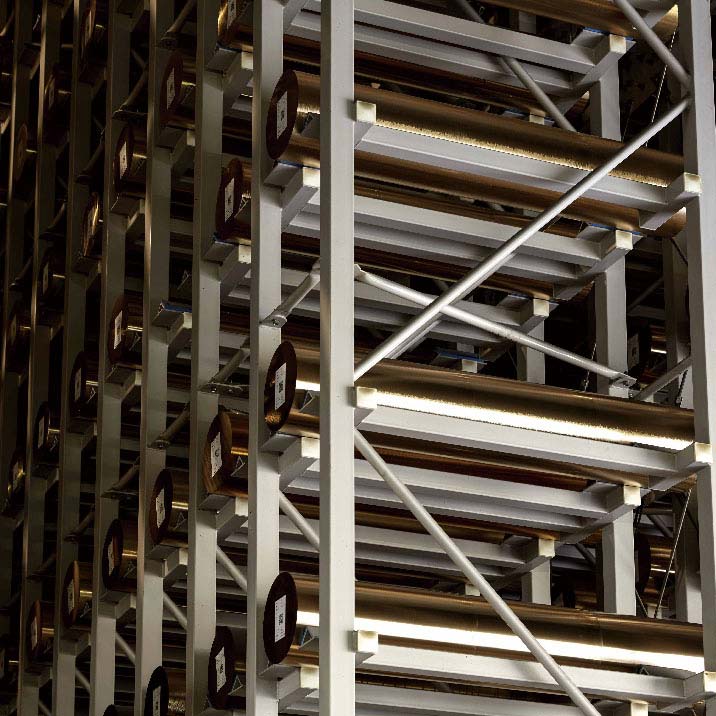

BILLET STOCKER

Our billet stocker, a big high-rise warehouse, stores a variety of billets manufactured according to customer requirements. This facilitates the speedy delivery of products to fill customers’ orders.

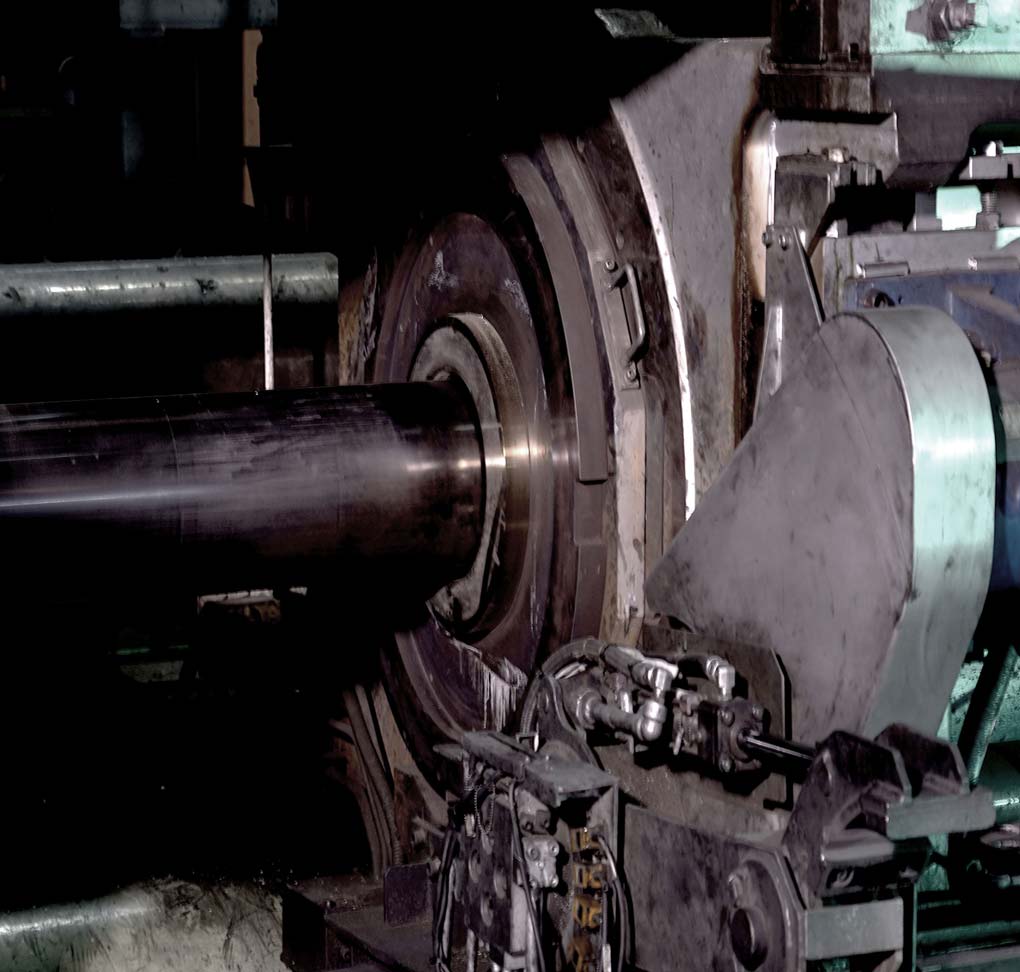

EXTRUDER

Our cutting-edge control system delivers high quality and production efficiency as well, by careful management of hot-extrusion tools such as dies.

COLD-WORK PROCESS

Optimum productivity is achieved by continuous drawing, cutting and chamfering throughout the cold-work process using the industry's longest cooling table and the world's fastest combined machine.

SHIPMENT

Products that meet customers' requirements are delivered to them via our associated trucking company network across the nation.